Transmission Oil Cooler line Manufacturers

information to be updated

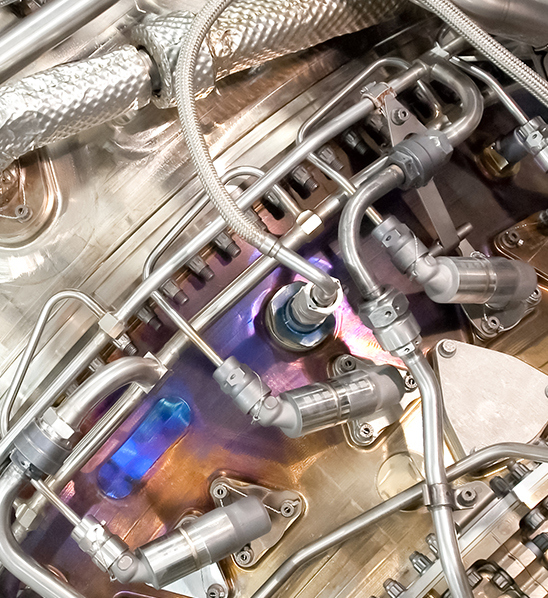

The Transmission Oil Cooler Line is a piping system connecting the automatic transmission and the transmission cooler. Its core function is to circulate automatic transmission fluid. Designed and manufactured specifically for modern, high-performance automatic transmissions, it is a critical thermal management component. This product maintains transmission temperatures within the optimal operating range, effectively preventing premature oxidation and failure of ATF and eliminating the risk of overheating and wear of internal components.

Product Features:

Efficient Heat Dissipation

Optimized internal wall finish and bend radius ensure minimal ATF fluid circulation resistance and maximum flow rate, maximizing cooling efficiency.

Adaptable to Extreme Environments

The pipe body features a chemically resistant synthetic rubber inner layer, a high-strength fiber or wire braided middle layer, and an ozone- and aging-resistant outer layer. This eliminates the aging and rust-clogging issues of traditional rubber hoses and metal hoses, while also improving resistance to vibration fatigue.

Leak-Proof Safety

Engineered with either integrated snap-fit ??or patented push-fit connectors, the connection is secure and easy to install, and features double or multiple O-ring seals.

Flexibility and Ease of Installation

The pipe shape is custom-made to original equipment (OE) specifications, perfectly fitting the complex spaces of the vehicle chassis and engine compartment. Wide Range of Vehicle

Coverage

Flexible use of steel, aluminum, or composite hoses allows for tailored fit to meet varying pressure and vibration absorption requirements.

About JIATIAN

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

Honors and Certificates

News and Information

-

Is Your Automatic Transmission Overheating? A Key Component You're Ignoring Could Be the CauseUnderstanding the Hidden Dangers of Transmission Heat and How a Simple Line Can Save Your Expensive Transmission Every day, countless drivers get behind the wheel, turn the key, and head off to their destinations, placing their co...view More

Dec 15, 2025 ? Industry News

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be frustrating and concerning. While...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’re stopped at a traffic light. ...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the exhaust brake should be desig...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts have experienced this: Why is...view More

Oct 27, 2025 ? Industry News

I. Basic Cognition: Core Connection Between Transmission Thermal Management and Cooler Lines

1. Definition of Core Concepts

| Concept | Professional Definition |

|---|---|

| Transmission Oil Cooler Line | A piping system connecting the automatic transmission and the transmission cooler, whose core function is to realize directional circulation of ATF and complete heat exchange |

| ATF Thermal Management | A technical system that prevents ATF oxidation failure and overheating wear of internal transmission components by controlling ATF temperature within the optimal range (usually 80-90℃) |

| Pipeline Weather Resistance | The ability of pipelines to maintain structural integrity and performance stability under complex environments such as high and low temperatures, corrosion and vibration |

II. Core Technology: Key Industry Indicators and Technical Advantages of JIATIAN Products

1. Key Industry Technical Indicators and JIATIAN Product Performance

| Key Industry Indicators | Industry General Standards | JIATIAN Product Parameters | Technical Selling Point Support |

|---|---|---|---|

| Heat Dissipation Efficiency | Pipelines must ensure ATF flow rate ≥2L/min and heat exchange efficiency ≥60% | ATF flow rate increased by 15% and heat exchange efficiency reached 72% | Optimized inner wall finish and bending radius reduce circulation resistance and maximize flow rate |

| Temperature Resistance Range | -40℃ to 120℃ | -50℃ to 150℃ | Outer ozone aging-resistant material + inner chemical corrosion-resistant rubber, suitable for extreme temperature environments |

| Sealing Reliability | Static sealing without leakage for ≥5000h | Static sealing without leakage for ≥8000h | Integrated snap-fit/patented push-fit connectors + double O-ring seals to eliminate leakage risks |

| Vibration Fatigue Resistance | Can withstand 10-2000Hz vibration with cycle times ≥10^6 times | Can withstand 5-3000Hz vibration with cycle times ≥2×10^6 times | Middle layer of high-strength fiber/steel wire braid enhances vibration fatigue resistance |

2. Technical Comparison Between Traditional Pipelines and JIATIAN Pipelines

| Pipeline Type | Material Structure | Core Defects | Technical Breakthroughs of JIATIAN Pipelines |

|---|---|---|---|

| Traditional Rubber Pipeline | Single-layer rubber + metal joints | Prone to aging and cracking, poor temperature resistance, and joint falling off under vibration | Three-layer composite structure (inner corrosion-resistant + middle vibration-resistant + outer aging-resistant) eradicates aging problems |

| Traditional Metal Pipeline | Single steel/aluminum pipeline | Difficult to bend, prone to rust and blockage, and poor adaptability | Supports customization of steel/aluminum/composite materials and OE specification forming to adapt to complex installation spaces |

III. Industry Trends: Pipeline Technology Innovation Direction Under Transmission System Upgrade

1. Core Directions of Industry Upgrade

- High Performance: The thermal load of transmissions (reducers) of new energy hybrid/pure electric vehicles has increased by more than 30%, putting forward higher requirements for pipeline heat dissipation efficiency

- Integration: The vehicle chassis space is becoming increasingly compact, requiring pipelines to have better customized forming and integrated installation capabilities

- Longevity: The vehicle warranty period has been extended (some brands reach 8 years/200,000 km), and pipelines need to have longer weather-resistant service life

2. Trend Adaptability of JIATIAN Products

- Responding to High Performance: The high-efficiency heat dissipation design of JIATIAN pipelines (15% increase in ATF flow rate) can meet the high heat dissipation demand of hybrid transmissions, and its laboratory full-performance testing system ensures stability under extreme working conditions

- Adapting to Integration: Relying on 10 CNC fully automatic pipe bending machines and hydraulic internal forming equipment (maximum processing length 1.5m, pipe diameter φ10-φ80), OE-level customization of complex paths can be realized to adapt to compact installation spaces

- Supporting Longevity: The three-layer composite material + multi-channel sealing technology makes the service life of pipelines 50% longer than that of traditional products, matching the long warranty period of the whole vehicle

FAQ:

-

Q: Can JIATIAN Transmission Oil Cooler Line adapt to the modification needs of non-original vehicle models? A: Yes. JIATIAN has complete customized R&D capabilities. According to the transmission model, chassis space and heat dissipation demand of modified vehicle models, relying on hydraulic internal forming, laser welding and other equipment, it can customize exclusive pipeline solutions while ensuring the sealing and heat dissipation performance after modification.

-

Q: Does the three-layer composite structure of the pipeline have advantages in maintenance cost compared with the traditional single-layer rubber pipe? A: It has significant advantages. The traditional single-layer rubber pipe needs to be replaced every 2-3 years on average, and it is easy to cause transmission failures due to leakage (high maintenance cost); the service life of JIATIAN three-layer composite pipeline can reach more than 8 years, without rust and aging blockage problems, which can greatly reduce the maintenance and failure repair costs in long-term use.

-

Q: How does JIATIAN ensure the factory performance stability of products? A: JIATIAN has built a comprehensive laboratory. All pipelines must pass multi-dimensional tests such as temperature resistance, pressure resistance, vibration fatigue and sealing performance before leaving the factory; at the same time, relying on 2 large-scale brazing furnace production lines, 4 fully automatic laser welders and other advanced equipment, it realizes full-process quality control in production and ensures the consistent performance of each batch of products.

-

Q: Can JIATIAN's cooling pipeline be used for electric drive transmissions of new energy vehicles? A: It is fully compatible. JIATIAN has developed special composite material pipelines for the high thermal load and high insulation requirements of new energy electric drive transmissions. Its heat dissipation efficiency can meet the temperature control demand of electric drive systems, and it has excellent electrical insulation, and can be customized with OE specifications to adapt to compact installation spaces.

English

English Espa?ol

Espa?ol