Automotive Fuel Line Manufacturers

information to be updated

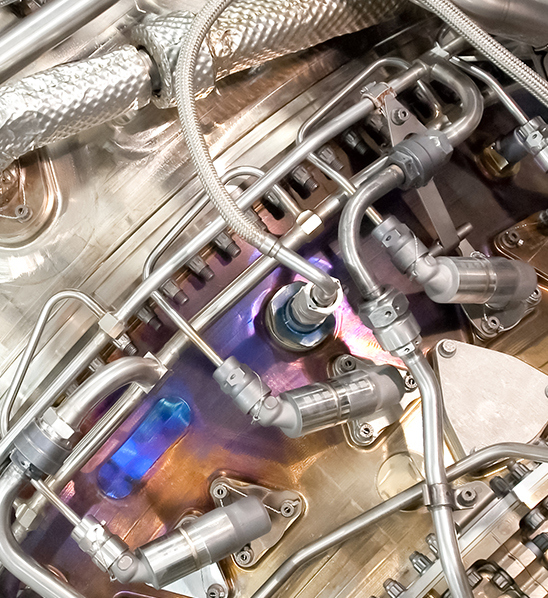

The Fuel Line is the critical fluid pathway that transports fuel from the tank to the engine or other combustion devices. It performs functions such as pressurization, filtration, and distribution, and is widely used in power systems such as automobiles, aviation, marine vessels, and construction machinery.

Product Features:

Utilizing high-performance materials that are resistant to corrosion, high temperatures, and high pressures, the Fuel Line ensures leak-proof and corrosion-free operation even under extreme operating conditions.

It includes subsystems such as low-pressure and high-pressure delivery pipes, filters, pressure regulators, and fittings, forming a compact, modular piping network for easy on-site assembly and maintenance.

O-rings, bellows ends, or specialized sealing gaskets provide a reliable seal, preventing fuel leakage and impurities from entering.

Pre-filters, fine filters, and sedimentation buffer filters are installed before the fuel enters high-pressure components to remove particles, moisture, and paraffin, improving fuel quality and protecting the injection system.

A variety of quick-release, leak-free connections are available, including threaded, snap-fit, compression fittings, and DOT SureLock, facilitating rapid replacement and maintenance.

The selection of high-strength, lightweight materials and optimized pipe diameters reduces overall weight, improves fuel economy, and complies with increasingly stringent emissions regulations. Complying with ISO4413 and other safety standards, it has anti-vibration and anti-shock design to ensure stable operation in vibration and shock environments

About JIATIAN

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

Honors and Certificates

News and Information

-

Is Your Automatic Transmission Overheating? A Key Component You're Ignoring Could Be the CauseUnderstanding the Hidden Dangers of Transmission Heat and How a Simple Line Can Save Your Expensive Transmission Every day, countless drivers get behind the wheel, turn the key, and head off to their destinations, placing their co...view More

Dec 15, 2025 ? Industry News

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be frustrating and concerning. While...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’re stopped at a traffic light. ...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the exhaust brake should be desig...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts have experienced this: Why is...view More

Oct 27, 2025 ? Industry News

Core Definition and Application Boundaries of Fuel Lines

1. Core Concept Definition

2. Application Scenario Classification and Adaptation Requirements

|

Application Scenario |

Core Working Condition Requirements | JIATIAN Product Adaptation Selling Points |

|---|---|---|

| Automotive Field | High-frequency vehicle vibration, wide temperature range of -40℃~120℃, ultra-low leakage rate | Professional anti-vibration structure, O-ring/bellows double sealing, lightweight alloy pipe |

| Construction Machinery | High dust erosion, strong acid-base corrosion, high-pressure impact of 10-35MPa | Corrosion-resistant and high-pressure special materials, three-stage progressive filtration system, quick-connect leak-proof joints |

| Marine/Aviation | Long-distance transmission, high sealing performance, high salt spray corrosion environment | Compact modular pipeline network, DOT SureLock anti-loosening joints, salt spray corrosion-resistant coating |

3. Core Component Composition

Key Performance Indicators of Fuel Lines and JIATIAN's Technical Advantages

1. Industry Core Technical Indicators and Product Compliance

| Technical Indicator | Industry General Standard Requirements | JIATIAN Product Measured Parameters | Core Technical Advantages |

|---|---|---|---|

| Temperature Resistance Range | -30℃~100℃ | -40℃~150℃ | Adopts high-temperature resistant special rubber and metal composite pipes, suitable for extreme temperature difference working conditions |

| Pressure Resistance Level | Regular ≤25MPa | Can withstand up to 35MPa | High-strength lightweight alloy pipe + optimized pipe diameter design, balancing pressure resistance and lightweight |

| Filtration Precision | Regular ≥10μm | Front pre-filtration (50μm) + sedimentation buffer filtration + fine filtration (5μm) | Three-stage filtration can remove 99.5% of particles, moisture and paraffin, fully protecting the injection system |

| Seal Leakage Rate | ≤5×10??m3/s | ≤1×10??m3/s | Double sealing structure of bellows end + special sealing gasket, achieving ultra-high standard sealing |

| Anti-vibration Level | Meets ISO 16750-3 vibration standard | 20% better than ISO 16750-3 standard | Exclusive anti-vibration and anti-impact structural design, suitable for high-frequency vibration scenarios of construction machinery |

2. Core Technical Principles?

- Multi-stage Filtration Principle: The three-stage filtration system of JIATIAN's fuel line adopts the logic of "progressive impurity interception". Fuel first passes through the front pre-filter to intercept large particles above 50μm, then separates moisture and paraffin through the middle sedimentation buffer filter, and finally filters fine particles below 5μm through the end fine filter to ensure that the cleanliness of the fuel entering the high-pressure injection system meets the standard.

- Sealing and Leak-proof Principle: The product adopts "double sealing protection". Custom O-rings are equipped at the pipeline joints, and integrated welded sealing gaskets are used at the bellows ends. At the same time, various types of quick-connect joints such as thread, buckle, and DOT SureLock are used, which not only ensure the connection strength, but also fundamentally prevent fuel leakage and impurity intrusion.

Upgrade Direction of Fuel Lines and Forward-looking Adaptation of JIATIAN's Products

1. Industry Core Upgrade Trends and Product Adaptation Solutions

| Industry Upgrade Trend | Core Market Demand | JIATIAN Product Adaptation Solution |

|---|---|---|

| Lightweight | Reduce pipeline weight and improve equipment fuel economy | Use high-strength lightweight alloy materials, optimize pipeline diameter, and reduce overall weight by more than 15% |

| Low Emission | Improve fuel cleanliness and adapt to National VI/Euro VII emission regulations | Three-stage filtration system + precise fuel distribution structure, reducing combustion impurities and helping equipment meet strict emission requirements |

| Intelligence | Integrate pressure monitoring module to realize early fault warning | Reserve pressure sensor interface, and can expand intelligent monitoring functions as needed (support customized development) |

| Modularization | Shorten assembly cycle and reduce later maintenance costs | Modular pipeline network + quick-connect joint design, improving on-site assembly efficiency by 30% |

FAQ:

-

How long is the service life of JIATIAN's fuel lines? JIATIAN's fuel lines adopt corrosion-resistant and high-pressure special materials and integrated sealing technology. The service life can reach 8-10 years under normal working conditions, and even in harsh working conditions such as construction machinery, the service life can reach more than 5 years, far exceeding the industry average of 3-5 years.

-

Does the product support non-standard customization? Yes. JIATIAN is equipped with 10 CNC automatic pipe bending machines, 8 large-scale machining centers and a professional R&D center. It can provide customized fuel line design and production services according to customers' pipeline length (up to 1.5 meters), pipe diameter (¢10-¢80) and specific working condition requirements. Moreover, the self-developed water expansion bellows technology can realize high-precision forming of complex pipeline shapes.

-

Has the product passed relevant industry authoritative certifications? JIATIAN's fuel lines have passed ISO4413 safety standard certification and also comply with relevant quality system certifications in the automotive industry. The core indicators such as temperature resistance, pressure resistance and sealing of the products have all passed third-party laboratory testing, and complete certification reports can be provided to customers.

-

Do the filter elements of the multi-stage filtration system need to be replaced regularly? Yes. The pre-filter element is recommended to be replaced every 10,000 kilometers/6 months, and the fine filter element is recommended to be replaced every 20,000 kilometers/12 months; for construction machinery working conditions, it is recommended to shorten the replacement cycle by 50%. JIATIAN can provide matching filter elements and standardized replacement guidance to ensure the continuous effectiveness of the filtration system.

-

What are the precautions for product transportation and installation? During transportation, avoid collision of pipeline joints, and it is recommended to use JIATIAN's customized protective packaging; installation must be operated in accordance with the modular assembly manual, and the quick-connect joint must be confirmed to be locked in place (DOT SureLock joint has a locking prompt). It is strictly forbidden to privately modify the pipeline diameter and connection method, so as not to affect the pressure resistance and sealing performance of the product.

English

English Espa?ol

Espa?ol